|

Here is a close up of the area that still needs to be machined.

|

|

|

Both ends cleaned up nicely and and now

I'm going to add a little something that will be two-fold.

|

|

|

I'm going to add a piece of 1/4" thick black walnut to each end. This will

give it some contrast and second it will hide the end grain of the

base.

|

|

|

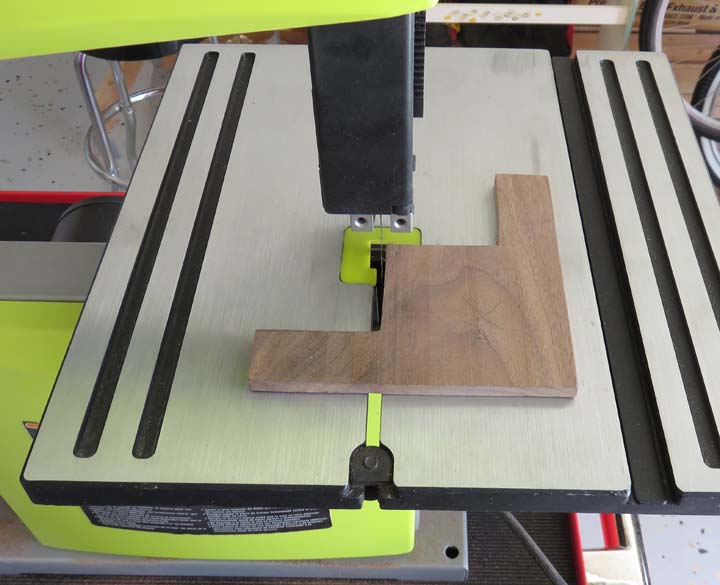

I traced around each piece and now I'm cutting off the excess with my

bandsaw. These will be glued to each end.

|

|

|

|

I didn't have any clamps that would hold this correctly

so I improvised. First I placed a nice flat piece of steel on my work bench, glued both pieces to the

ends and then added some weight to

the top (which acts like a clamp). In case you were wondering, the red

piece is a small anvil and the top piece is a small section of rail road track.

Whatever works you know...

|

|

|

The next day I removed my weights (clamps) and now I'm ready to machine

away the excess.

|

|

|

|

To machine away the unwanted material I had to make

multiple setups. Here I'm machining the bottom and the second step on the

right-hand side. Once I was finished with this end, I moved the base to

the other side of my vise and repeated the machining. I did this for every side,

which was time consuming but worked out great. I also stayed away a

couple of thousandths and sanded the remaining material flush.

|

|

|

|

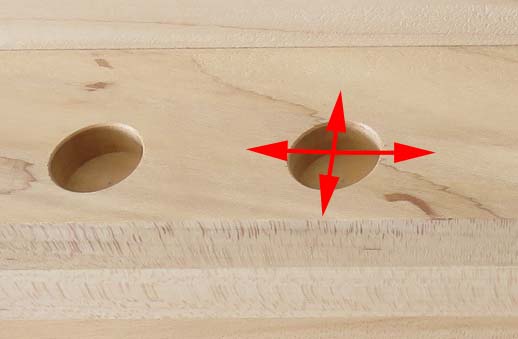

The next step was to make pockets for all the weights. I did

this with a 3/4" diameter end mill. If you look close

you'll see that the pockets are not centered. I have a reason for this

that I'll talk about later.

|

|

|

|

With the weights being 3/4" diameter and my end mill

being exactly the same size, the pockets were not going to be larger

enough. To have the weights fit nice and easy, I moved over .003 in each direction

(arrow) which made the pockets slightly larger.

|

|

|

|

If you're wondering: are the pockets round by

doing it this way? No. Will the weights fit correctly doing it this way?

Yes they will. And if I didn't tell anyone about it, no one would ever

know. Just a little machinist trick here. I also chamfered the holes to aid

when putting the weights in.

|

|

|

I'm using a corner rounding end mill with a 1/8" radius on a few

edges. I would have used my router table but with this irregular shape

now, that wasn't going to work for me.

|

|

However I was able to use my router table on the outside edges. Again

I'm using a 1/8" radius.

|

|

|

1

2

3

4 |