|

My daughter Angela and her husband Matt like to host a

few games of Binger after Easter dinner but the board they have isn't to

their liking. I told them I'd make them a new one but would like some

input/direction on what they'd want first. A day or two later we had a

plan and now it's time to cut some wood.

Bingo Board I'll be using black walnut and maple for

this project, which should look nice together. The size will be 12" tall

X 10" wide and each piece of wood will be two inches making up the

width.

|

|

|

I fired up my table saw and ripped my

pieces two inches wide. And as you can see, I'll be using three pieces

of black walnut and two of the maple.

|

|

|

|

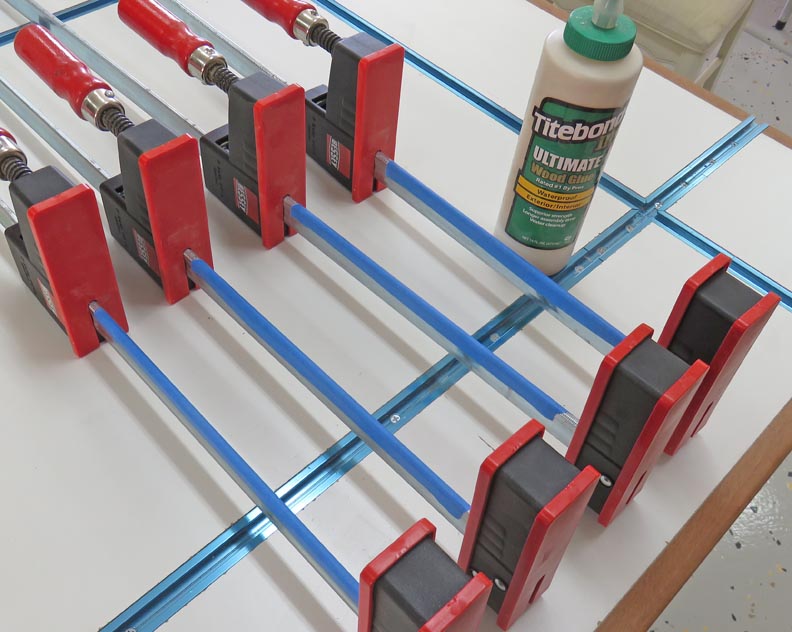

The next step is to glue these five pieces together and

to make that happen I'll use my parallel clamps. These clamps have

serrations on the working surface which is for the clamping mechanism. To

help keep glue out of these serrations, I cover them with painters tape.

The next day I removed the work piece along with the tape keeping my

clamps glue-free.

|

|

|

I use painters tape all the time but don't buy the cheep stuff, I

like to use the 3M brand because it works much better than the other

junk.

|

|

|

|

The next day I ran the board through my planer and

cleaned up both sides. Now this surfacing process goes really quick. In

fact it took longer to move the machine away from the wall, set it in

place, get the dust collection hooked up and then set the correct height

than it does to make two or three passes with the unit.

|

|

|

I left a small amount on the length to cut off later, which is what I'm

doing here. I used my cross-cut sled for this and again, it took longer

to setup than it did to cut both ends of my work piece.

|

|

|

A few minutes with my DA sander had both sides feeling nice and smooth.

|

|

|

|

Milling Machine

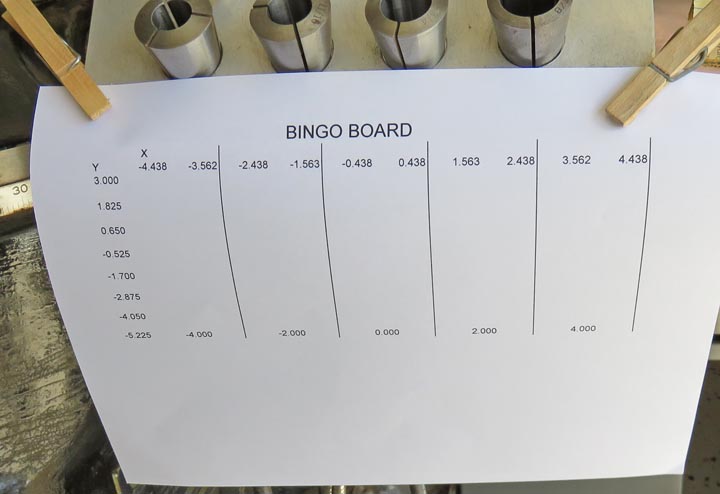

I'll be using my milling machine to put in all the

pockets for the game balls. To make sure I have each one in the right

place I made a cheat-sheet to help me. I'm not sure if you've ever

thought about it, but a Bingo game has numbers 1 thru 75 that you play

with. That means I'll need to make 75 pockets.

|

|

|

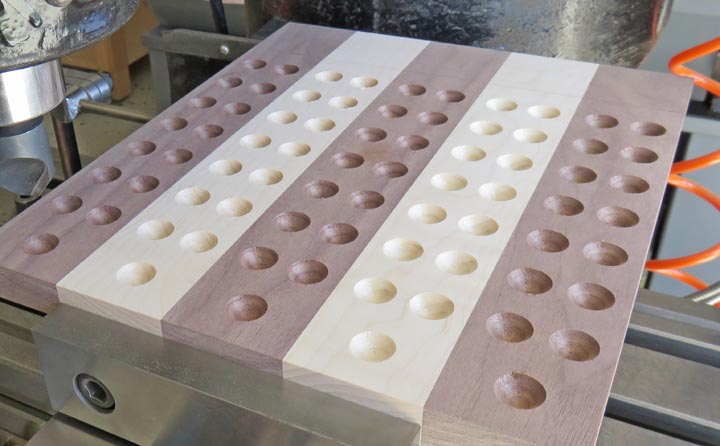

I'm using a 1/2" ball end mill for this and it worked great. So...what

do you think so far?

|

|

|

|

The game balls are 5/8" diameter and with my end mill

only being 1/2" diameter, I needed a pocket that was a little bit

larger. What I came up with is to use a chamfer tool to make the top

portion of the pocket larger, which should keep each ball from

accidentally moving if someone bumped the board.

|

|

|

|

1

2

3 |