|

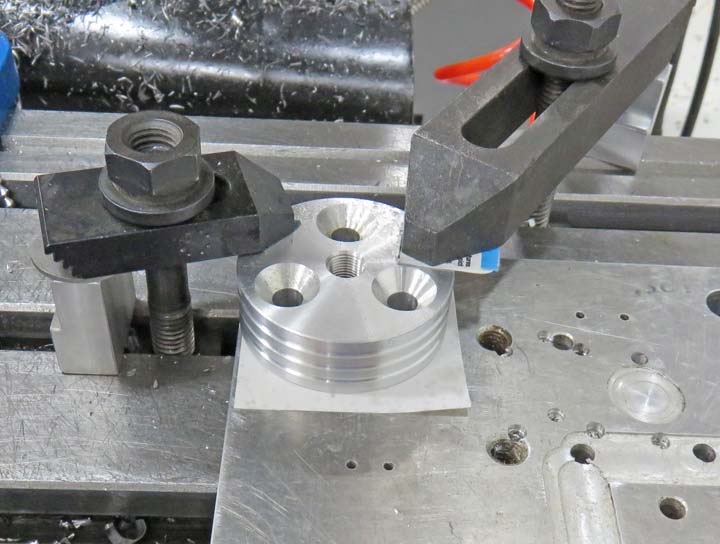

I'll be using the three existing threaded holes on the cam to attach my adapter

to. Here I'm drilling and chamfering for some 3/8" flat head cap screws.

This should work pretty good and it won't add much weight either.

|

|

|

|

The next thing I'll be doing is attaching the cam to the

base. I had a couple of ideas here but the easiest way was to weld them

together. Before I welded anything, I wanted to make sure the two

surfaces were nice and square. To do that I took a clean-up cut on the

end of the cam so it would be square. I did the cut on my milling

machine using the same tooling that I drilled it with. Here I'm using some 1/4" all-thread that is placed through

both pieces to use as a clamp.

|

|

|

|

Here is the bottom along with a few different size

washers and finally a 1/4" nut to finish it off with. Once I had

everything clamped in place, I used my calipers to make sure the cam and

base were centered.

|

|

|

This was an easy process and it didn't take long to weld.

|

|

|

I don't think these will ever come apart because I put the heat to it.

So far I'm happy with it and it stayed straight.

|

|

|

Here you can see the adapter screwed on and now I'm ready for some lamp

hardware.

|

|

|

If you're wondering what the sparkplug is for, I'll be using it to hold

on to while turning the light on and off. It will be a fancy pull chain

knob.

|

|

|

|

The light socket had a really short pull chain on it which I

didn't like. And I didn't want to have one of those couplers visible

while holding the two chains together so I took the socket apart and

added the one I bought.

|

|

|

|

Some sparkplugs have a screw on top so I made sure to

buy one like that. The reason for this is so I could attach the pull

chain to it somehow. After playing with it for a few minutes, I didn't

like how things were going. Time for plan B.

|

|

|

|

I found another screw on piece that I had laying around

(bottom) and decided to make a small change. While I was crimping the

first one, the material cracked and I wasn't happy with it.

|

|

|

|

The reason it cracked is because the wall thickness was

too thick so I sanded my other down to make it thinner (arrow). This

should allow me to bend or crimp this area much easier now.

|

|

|

1

2

3

4

5

6 |