|

Working With Metal Continued

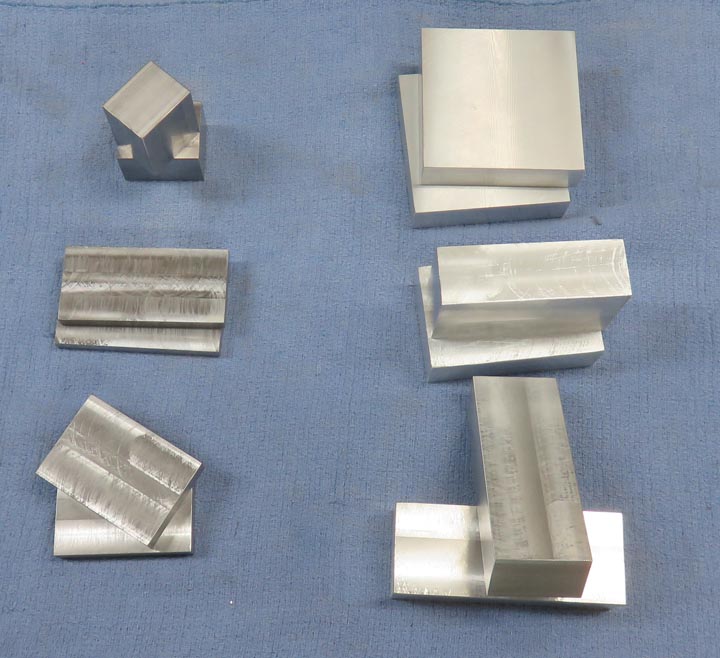

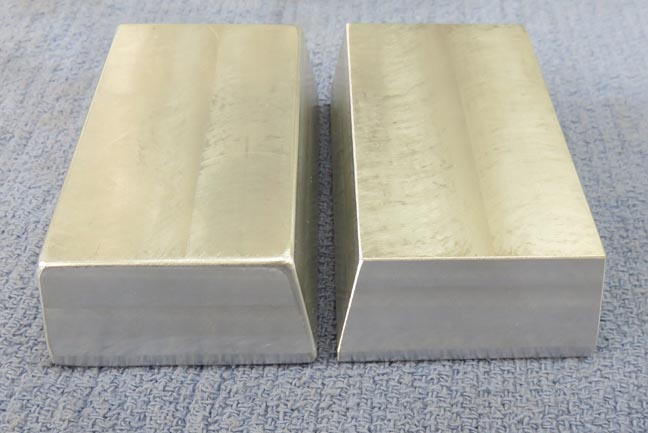

After about an hour, I've machined all six sides of the bars. Now

it's time to put a pocket in each one.

|

|

|

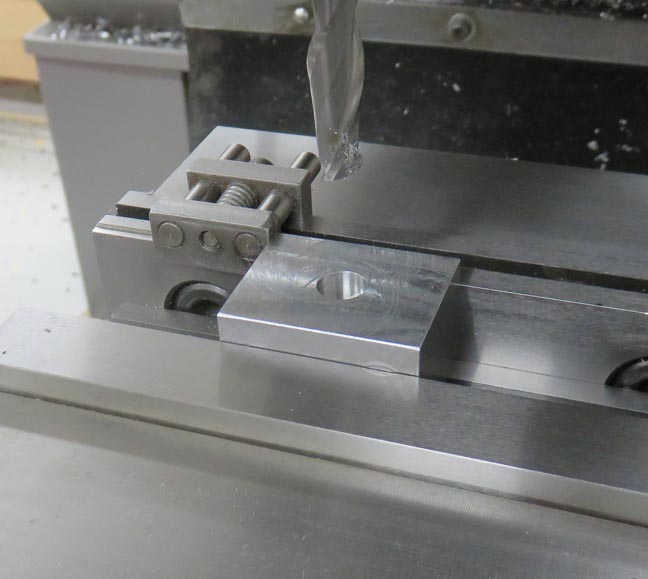

I'm using a 3/8" end mill to put a pocket

in each one that will be .150" deep. This pocket will locate on the 3/8"

pin on the balancing arm. This should keep the center of mass in the

correct place every time.

|

|

|

|

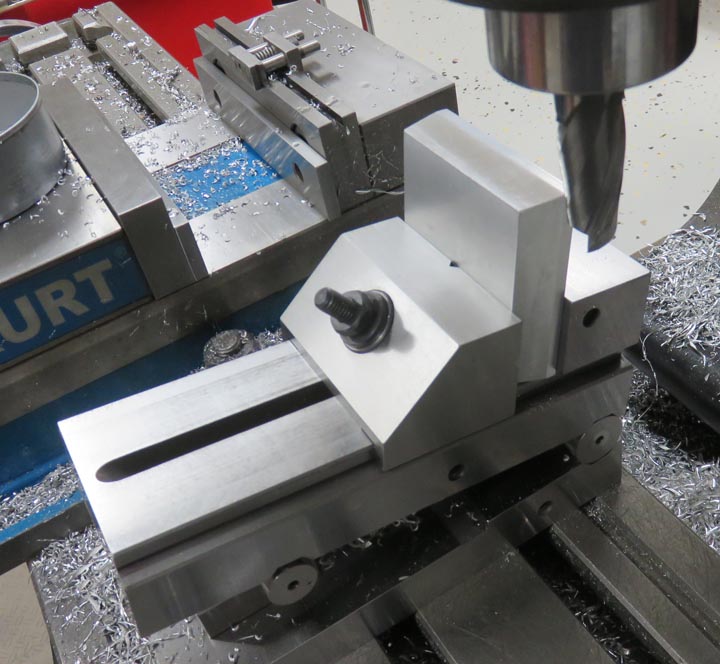

Here I'm using my sine vise to put a 10 degree angle on

four sides of the bars. This angle is to resemble a real gold bar

because they have tapered sides. Now I did leave a small straight

section at the bottom of each one, so they're easier to pickup.

|

|

|

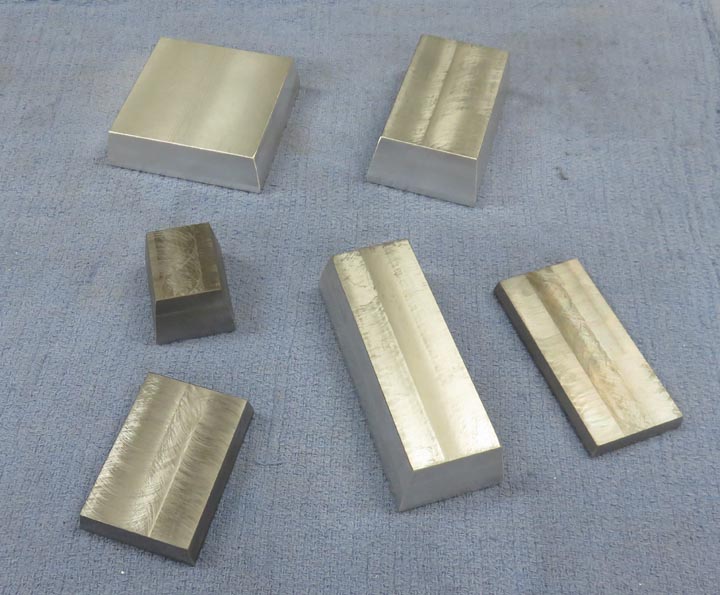

There we go, they all have 10 degree sides and are almost ready for

paint.

|

|

|

A close-up of the angles.

|

|

|

|

One last thing needed to be done was

to cut down some 10-32 screws, which will keep the end caps on. I used my Dremel

to remove about 1/4" which went fast. Then I used my belt sander to

deburr the threads.

|

|

|

|

I'm going to need some kind of weight to put inside each

cylinder and thought steel washers would work good for this. I'll be

using 5/16" and 1/4" washers for this, which should be easy to do.

|

|

|

I started with the small steel gold bar and add some washers as needed.

|

|

|

To make sure they didn't move inside the cylinder, I used some

bubble-wrap to fill the void.

|

|

|

By wrapping the bubble-wrap around the screw, this would create a nice

tight package.

|

|

|

|

1

2

3

4

5

6

7

8 |