|

Flag Pole Topper Continued I

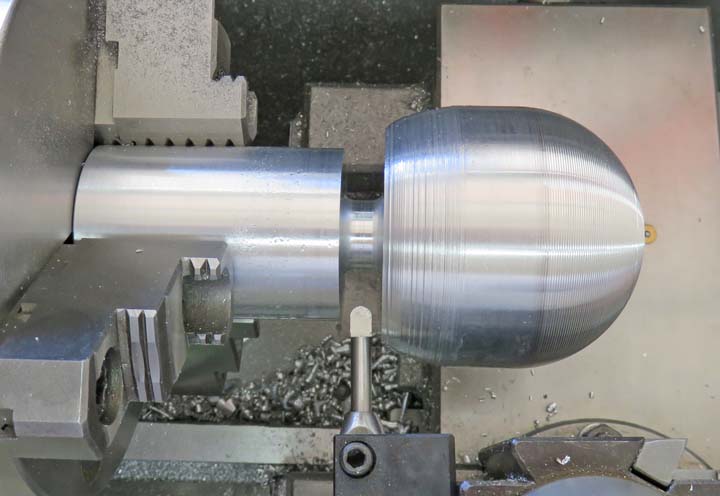

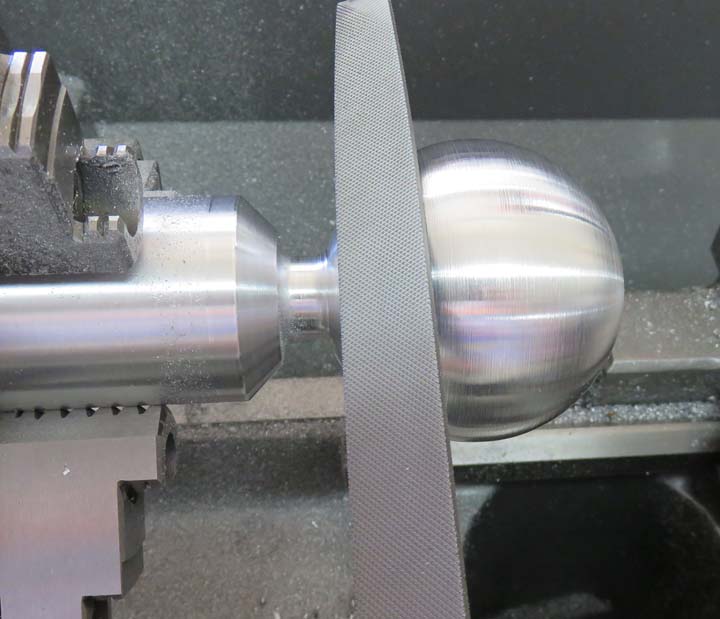

machined the one end and it's starting to look like I want. However, I

still have to do the opposite side so it becomes round. But before I do

that, I'm removing some material for two reasons: first I want to end up with

a 3/4" diameter under the sphere to help define it. And second, I need

room for my cutting tool to be able to cut the second part of this

sphere. The width of the groove is almost 1/2" with a 1/8" radius at

each end, which is what I'm doing below.

|

|

|

|

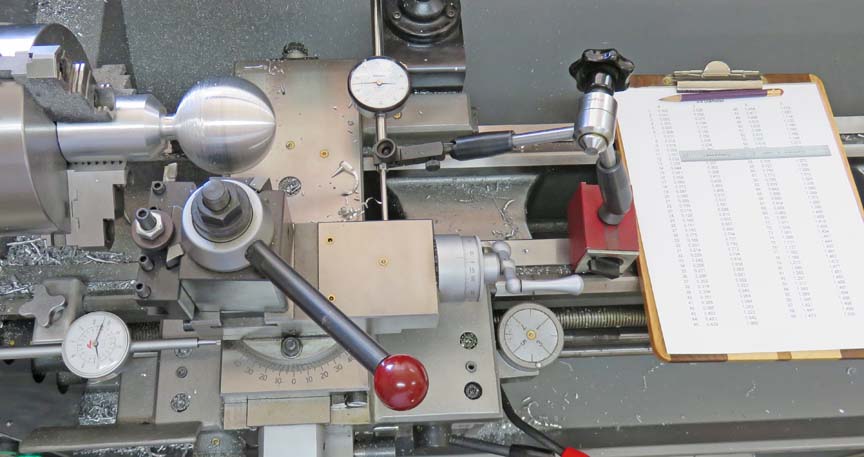

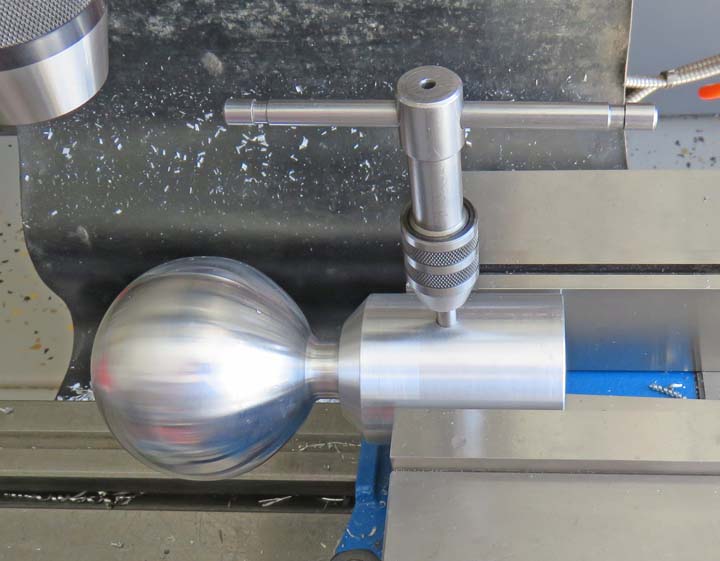

Here is my setup. By using two indicators, each having

2" of travel, I slowly created a series of steps at one degree

increments. The X and Z coordinates are on that paper to the right, all

90 of them. After I cut each step, I would move my six inch scale down

one line and then cut the next step.

I roughed this out first by staying away from the actual

dimensions three times before final cutting. First I stayed away by

.200", then .100" and last by .050". This method worked out really well

and when it came time for the final cut, things went pretty smooth.

|

|

|

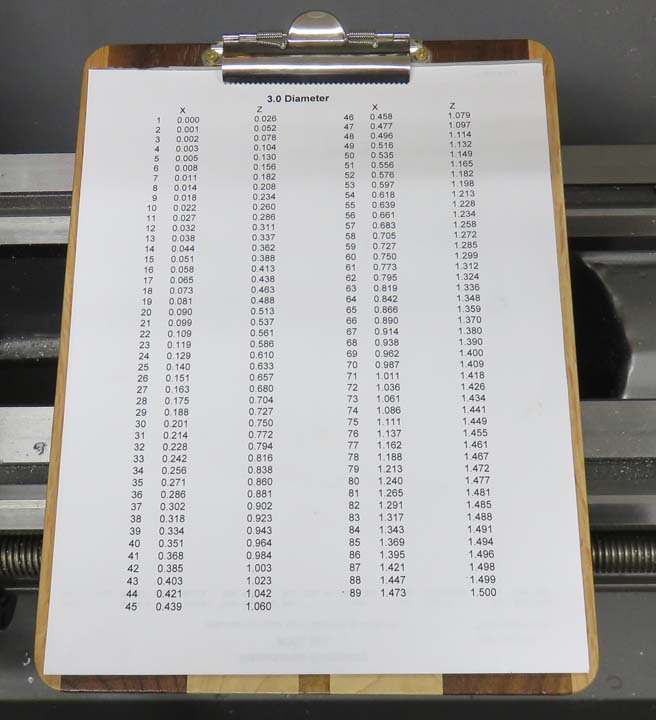

A close-up of all the numbers that I was working with. This took awhile

but I think you'll agree the end result was worth it.

|

|

|

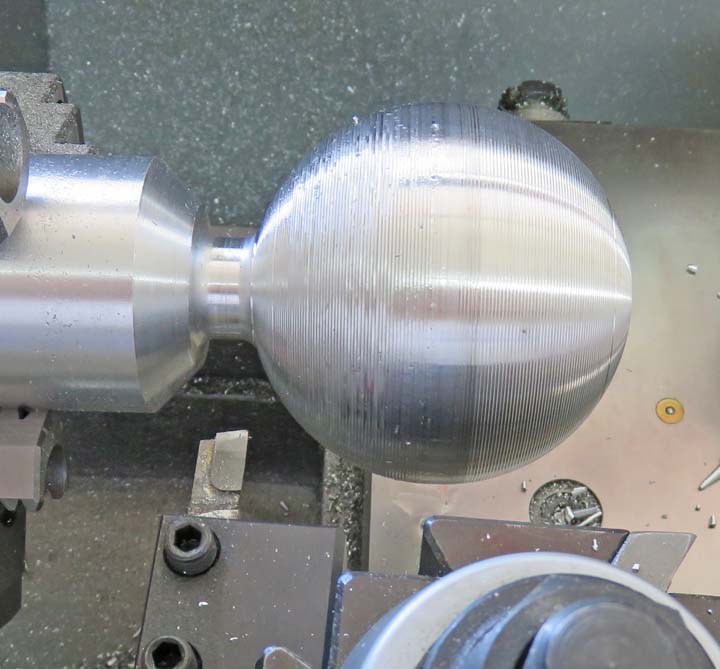

This is what I ended up with. And like I said, it's a series of steps.

Note the large 3/8" chamfer that I added as well.

|

|

|

With the use of a file, I slowly worked away all the steps and ended up

with a much smoother surface.

|

|

|

And here is what it looks like after some sanding. I know it looks out

of focus but it's not.

|

|

|

Here I've drilled a clearance hole for a screw and I'm tapping some

1/4-20 threads in the opposite side. However, these threads don't go all

the way through.

|

|

|

|

Here is what the other end looks like. The pole (larger

tube) will fit inside the larger counterbore, which is 1/2" deep. And the

smaller bore, which is 2" deep will fit over the inner steel tube and will be

held in place by a flathead screw.

|

|

|

Here I'm drilling a clearance hole for the 1/4" screw in the steel tube.

Once the pole topper is in place, it will cover the end of this tube by

1/2".

|

|

|

|

1

2

3

4

5

6

7 |