|

I'm cutting a pocket on the 15 degree angle for the

handle here. I'll also be drilling and tapping some 1/4-20 threads as

well. In order to do this I had to tip the head of my milling machine to

the same angle as my work piece.

|

|

|

|

Here is the handle, which I'm not happy with. At least

not yet. As I was machining the center part for the handle, I

wasn't liking the area the setscrew was in so I decided to change it.

|

|

|

What I'm getting ready to do is remove that smaller diameter altogether.

Then I'll go back to the mill and put another hole for the setscrew.

So...now you see it...

|

|

|

And now you don't. This will be a cleaner look and will sit against the

safe door a little better.

|

|

|

|

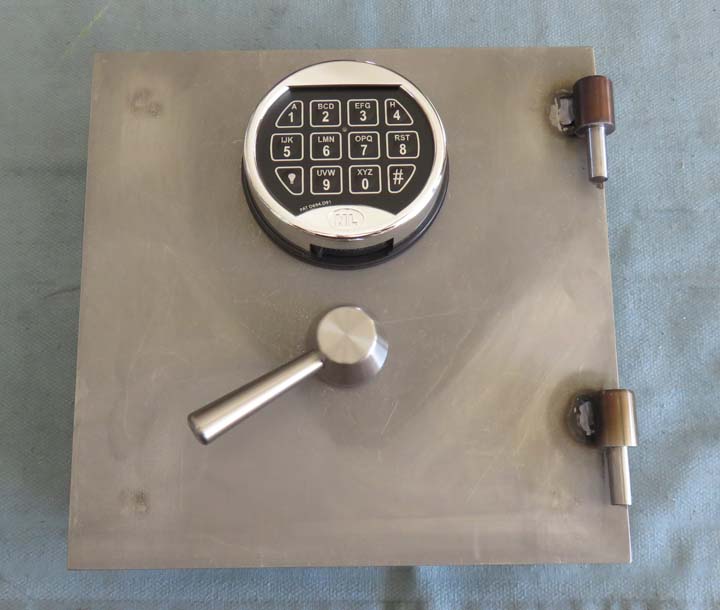

Now you can see why I went with one spoke for the

handle. I just didn't have the room to have three or more spokes as they would

be in the way of the key pad. And yes I thought about using three spokes

and having the two facing upward in this way - 'Y' - (with one leg

facing downward) but it was going to be to

crowded in my opinion. Anyways, this will be the look and I hope he

likes it.

|

|

|

|

Paint & Body Work

I haven't done any paint and body work in a long time

so this will bring back some memories of working on my 1971 Camaro from

yesteryear. What I have below is (left to right) body filler or Bondo,

primer and for the pin holes, glaze. The body filler and glaze are a two

part mix and once I opened the can of Bondo, the smell brought me back

to those good old days.

|

|

|

|

I mixed both products right on my work bench because it's

covered with a thick piece of sheet metal. This works great for this

kind of thing because it makes easy clean up with some lacquer thinner.

I used my putty knife to mix with but used a plastic paddle to apply it.

|

|

|

I didn't need very much because there wasn't and large dents, just a few

low spots here and there.

|

|

|

|

What I really wanted to do is make all the weld joints

even so I made sure to bring all of them to a sharp edge. Once they were

all at this stage, I went back and rounded them all the same size.

|

|

|

|

Once I had most of the rough work done, I needed to fill

some smaller areas. This is where the glaze comes in, it works great for

this kind of thing. I put tape next to the areas that needed attention

so I didn't forget (more on other sides).

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24 |