|

Working With Wood Continued

Here I'm machining the thickness and the radius at both ends which

worked out pretty good. After I cut each piece, I then went back to my

band saw and cut the rounded ends.

|

|

|

| Working With Metal Again

I'm using a file to produce a radius so I

can weld on the rings to this piece of steel. This piece of steel

measures 3/4" wide by 1/8" thick.

|

|

|

Using a hand file wasn't my first choice but I only had to do three

pieces so no big deal.

|

|

|

|

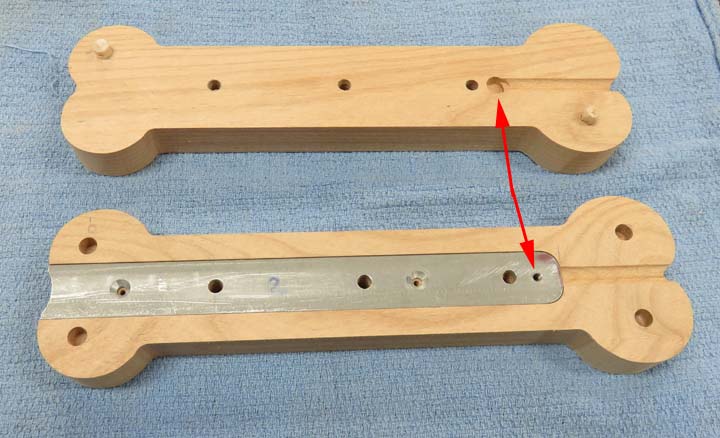

Assembly I mentioned earlier that the wire will be held to the

steel piece with a #8 screw. The arrows are pointing to the threaded

area in the steel and the other side is clearance for the head of the

screw.

|

|

|

After welding the ring to the flat piece, I used a sanding disc along

with a round file, and some Scotch-Brite to clean up my work piece.

|

|

|

Here is the hardware that will be used to hold the dog bones together.

These are 10-32 flathead screws and lock nuts with washers under the the

nuts.

|

|

|

I did some sanding and the put three coats of gloss clear on them, which

makes cleaning them easy.

|

|

|

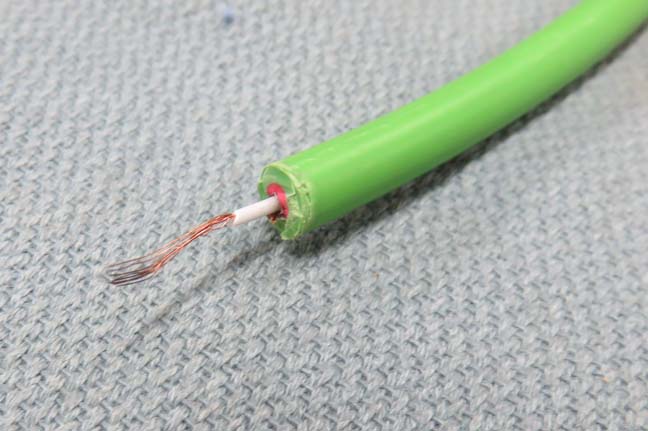

This instrument cable will be used to connect the dog bone to the

electronics that make this buzz wire operate.

|

|

|

This cable has two wires and I used the one in the center.

|

|

|

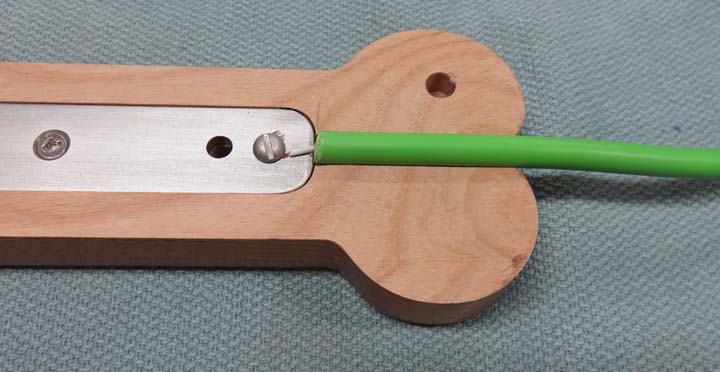

Here you can see how this is connected to that screw you saw earlier.

|

|

|

|

1

2

3

4

5

6 |