|

Working With Wood Continued

Here I'm cutting and fitting the mitered corners, which is something

I don't do very often. Going slowly here is time consuming, but it

works.

|

|

|

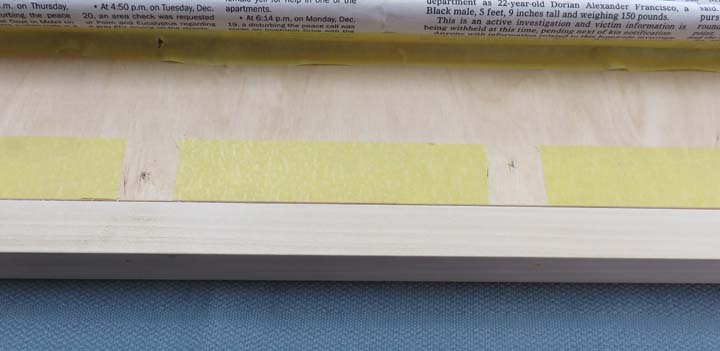

I glued and nailed the raised sides to the

plywood and then masked-off the top and bottom surface because I only

want to paint the raised sides.

|

|

|

|

As I was shooting some of the nails, I noticed the

newspaper moved in two places. And as you can see the nails came through

the top surface. Now it's time to fix them. I used some wire cutters to

remove the majority of of the nails but now I need to remove the small

amount next to the surface.

|

|

|

I used my Dremel and a carbide burr that has a rounded end to remove the

nail.

|

|

|

Next I applied some wood Spackle to fill the voids. An hour later I

sanded the filler flush and then re-masked my plywood again.

|

|

|

While the glue was drying on the table top, I started sanding on the

legs.

|

|

|

Once I had all the surfaces sanded, I filled all the nail holes with

Spackle.

|

|

|

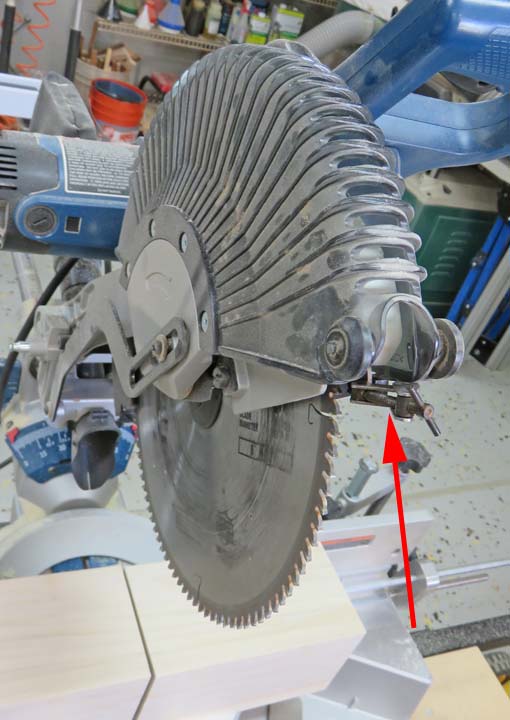

The next day I cut all the legs to 8 1/8" long, leaving them oversize by

1/8". Notice my work-stop (arrow) which made this process very easy.

|

|

|

I used a small clamp to hold the blade guard open while cutting (arrow).

This was to make sure the guard didn't drag across the sanded surface.

|

|

|

A close-up of the clamp I used, which is made by Kant-Twist. I have many

sizes of these types of clamps and they work so much better than any

C-clamp.

|

|

|

|

1

2

3

4

5 |