|

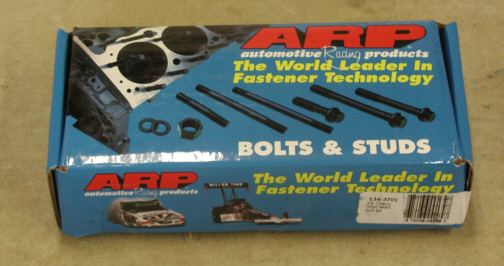

To keep the heads bolted down to the

block,

ARP got the nod once again. These bolts are heat treated to

190,000 psi and are much better than Grade 8 bolts.

|

|

|

Here you can see they have the same 12

point heads like the rod bolts do. This is a good thing because of the

larger valve springs on the heads. Because of the larger springs, it

makes it very hard to get at the bolt heads with a socket when

tightening them and with the small 12 point heads that these have,

there's no problem. The threads on these bolts are roll-formed instead

of cut. By roll-forming the threads, they become much stronger.

|

|

|

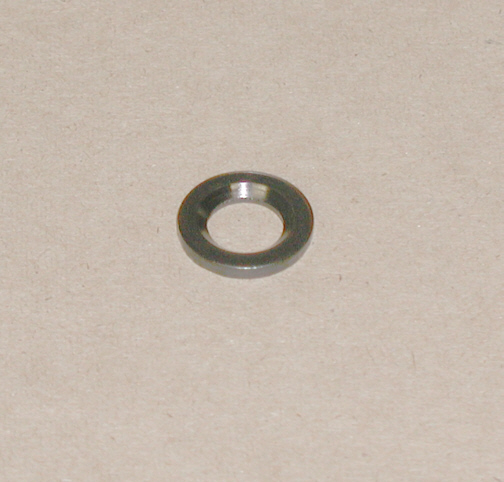

Notice the chamfer on the washer. This

is to clear the radius under the bolt head. These washers are also heat

treated and ground flat and then black-oxide coated like the bolts.

|

|

|

|

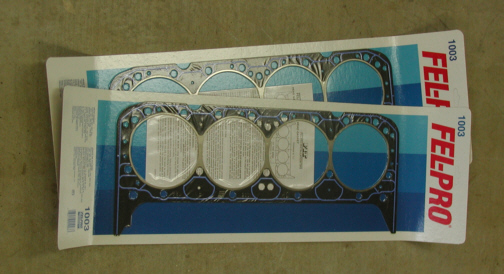

The head gaskets are made by

Fel-Pro

and are a composite type material. All of the gaskets I am using are

made by the same company.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18

19 20

21 22

23 24

25

26 27

28 29 |

|

30

31 32

33 34

35 36

37 38 39

40 41

42 43

44 45

46 47

48 49

50 51

52 53

54

55 |

|

56 57

58 59

60 61

62 63 |