|

Working With Plastic Continued

Now that my lathe is working again, it's time to turn those squares

into some round pieces. I made the diameter .735" to .740", which is

just under 3/4".

|

|

|

Here is what they look like all finished.

Now it's time to work on some aluminum again.

|

|

|

|

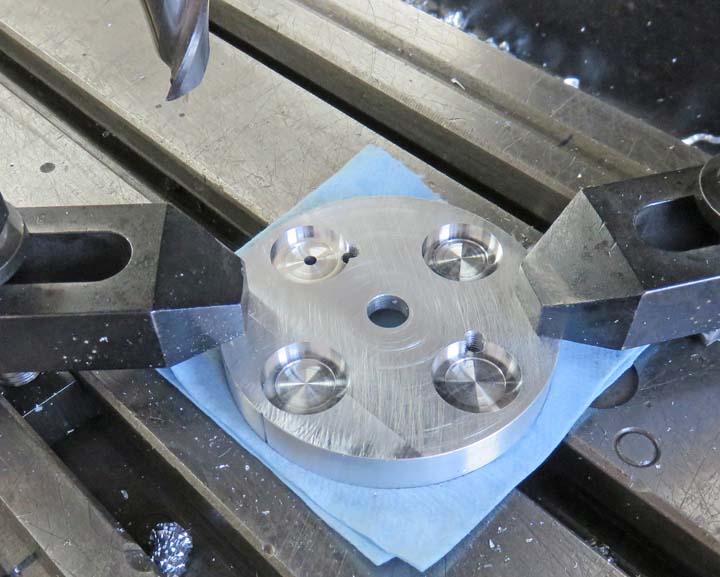

Working With Aluminum Again The depth of the pockets are .056" to .057". This way

the plastic stays proud by a few thousands. If you're wondering why

there are two different diameter pockets it's because I'm using an end mill

here. Let me explain: end

mills are ground so that only the outside edges cut while it's

traversing. To achieve this, the bottom of the end mill is ground at a

two or three degree angle.

This means if

you cut or plunge straight down (like I did below), the center won't be

as deep as the outer edge (leaving a high spot in the center). To get around this I used

a second smaller end mill, (in this case a 5/8" diameter one) to achieve a

much flatter area for the plastic to rest on. It's not a perfect

solution, but it's good enough for the plastic washer to sit flat enough

to work correctly.

|

|

|

I purposely centered one of the pockets around the 3/16" pin. This way

the washer

will ride on the slot instead of trying to go across

it when the aluminum piece is turned.

|

|

|

This is the 8 1/2" base which has the same concept as the smaller piece.

When the two pieces are fastened together, it feels like it's riding on

bearings, which is exactly what I wanted.

|

|

|

|

It's Finished

Here it is all finished.

|

|

|

There will be some vinyl stickers added to the areas near the lines I

machined in.

|

|

|

The base is 8 1/2" diameter and the other one is 7".

|

|

|

Here you can see a bunch of chamfers so nobody gets hurt.

|

|

|

Plus the chamfers make it look nice.

|

|

|

|

1

2

3

4

5

6 |