After making the lines that attach to

the radiator, I noticed that I was going to have some serious clearance

problems on the transmission side. My original plan was going to use

straight fittings on both ends of both the lines. These straight

fittings were to screw on to some 90 degree adapters that had 3/8"

pipe on one end (the trans side) and #6 AN on the other. I went to screw

the fittings into the transmission and they wouldn't work. One hit the

bottom of the floor as I turned it and the other hit the side of the

transmission case. Well that sucks because this meant that I had to

order some new fittings and send the others back. What you see below are

the new and improved way of running my lines. By using some brass 90

degree fittings on my transmission (they were very small) and then using

a "straight" pipe-to-AN adapter, I could use these 90 and 180 degree fittings to

clear everything. I know the 90 degree fitting will work because I tried

the one that was meant for the radiator (the one you see below with the

90 at the top and the straight fitting on the other end) and it worked so this gave me the

idea for the 180 fitting. It sounds weird but should work.

|

|

|

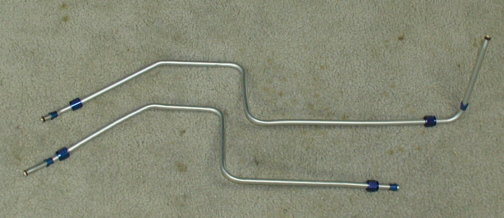

After making my new lines with the 180

and 90 degree fittings, I was able to cut these hard lines to length, flare

them and put the

sleeve and nut fittings on. These are ready to install at

this point.

|

|

|

|

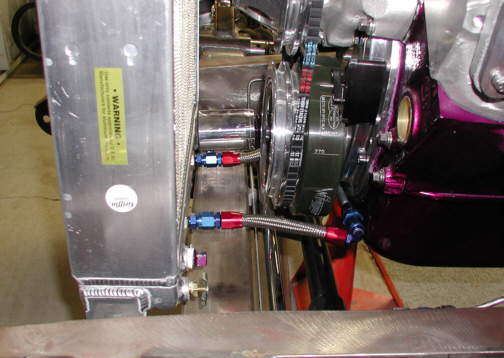

Here are the new braided steel

lines attached to the hard line. It's hard to see here but the hard line

runs under the timing cover between the damper and oil pan.

|

|

|

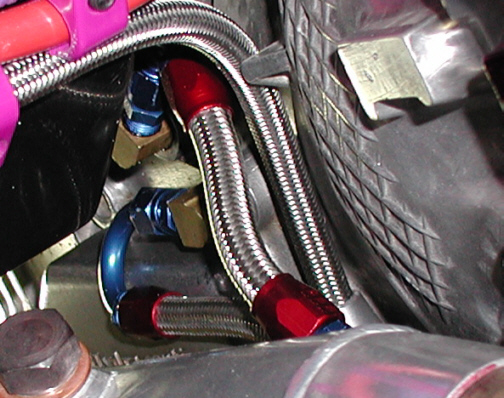

Here you can see the 180 and 90 degree

fittings along with the brass fittings I talked about earlier that go to

the transmission. The line on the right that bends toward the top of the

picture is not part of the transmission cooling. It's the transmission

dip-stick tube that runs to the firewall.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 |