|

Here is what the system looks like.

The red piece is the computer, wiring harness's, a bag full of hardware

and the programmer. Let's go through each piece one at a time.

|

|

|

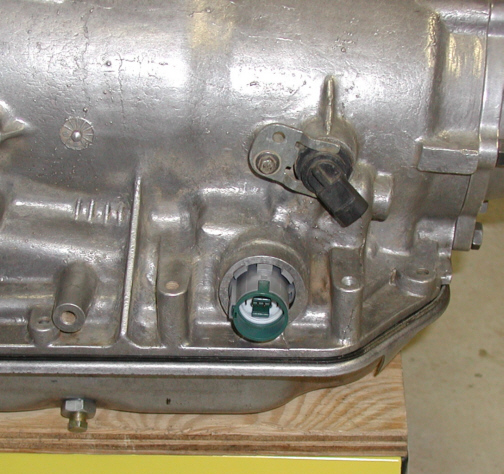

This is where two of the wires go from

the harness. The large round one plugs into the computer and the angled

black one goes to the throttle position sensor. The computer has to

talk to the transmission and in turn, the computer gathers in the

information and then tells the transmission what to do. It all depends

on throttle position. That's right....it has to know how far the gas

pedal is being pushed down and then the computer tells the transmission

what to do. How does it do that?

|

|

|

This is how it knows where the

position is. It does it with a unit called

Acculink

which is a "Throttle Position Sensor" or TPS. This unit bolts

on the carburetors linkage and moves along when the throttle is being

pushed. There is a sensor inside the black piece (like a rheostat) that

relays information back to the computer through three wires. The

computer has to know where the throttle position is to be able to

up-shift, down-shift along with a host of other things which we'll get

into later.

|

|

|

This is where the plug goes that has

the three wires. The linkage attaches to the round steel piece and is

adjustable. Now all this is very small and goes under the air filter,

next to the carburetor. I guess this is a brand new system that they

came out with in March of this year. The old way used a cable that went

to a box that does the same basic thing. Compushift gives you the old

setup just in case you want to use it. Let's take a look at it.

|

|

|

|

1

2

3 4

5 6

7 8

9 10

11 12

13 14

15 |