The long straight section is from the

12" side of the J-Bend along with a small amount of bend that was

needed to make the "S" shape that will be going over the rear

cross member. Because the "S" shape is so slight, the exhaust

should be able to move through here without much of a problem compared

to a tighter bend.

|

|

|

This is how it looks inserted into the

muffler. Now you can see why I needed those small cans (mufflers) because if they

were much longer, they wouldn't fit. I'll be putting some insulation

between the chassis and mufflers but in order to do that, I'll have to

dent the outside of the mufflers slightly to make enough

clearance. Turns out that the driveshaft hoop bracket, which is

1/4" thick, takes up the last bit of room (that I really don't

have) and fits tight against the chassis now. This isn't a good thing

because it will probably make a bunch of noise inside the car and I

don't want that.

|

|

|

The straight piece here will attach to

the other straight section in the above picture that come out of the

muffler. I used the left over piece

from the J-bend (which was just enough) which will be going over the

rear-end housing. Now I have to attach the two straight sections

together. Why didn't I make all this in one piece? It's because I

wouldn't be able to install it once it was welded, so this had to be

made this way.

|

|

|

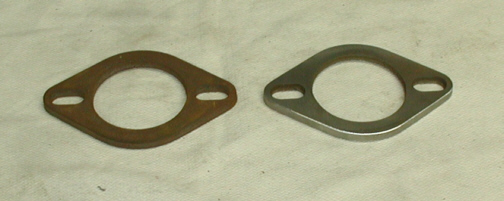

Here is how I'm going take apart the

system. By adding some flanges to the ends, I'll be able to take this

apart without a problem. Notice how rusty the one is on the left. This

is how I received them all but after sanding the front, back and sides, they

look much better and will weld easier.

|

|

|

|

1 2

3 4

5 6

7 8

9 10

11 12

13 14

15 16

17 18 19

20 21

22 23

24

25 26

27 28 |

|

29 30

31 32

33 34

35 36

37 38

39 40 |