|

Working With Steel Continued

I'm using my band-clamp (normally used for wood working) to squeeze

the ring onto the cardboard tube. Then I used my scribe to mark a line

that I'll cut to (arrows).

|

|

|

I used my Dremel and a cut-off wheel to

cut the steel with and I left the line while doing so because I'd rather have the rings

slightly lose than too tight.

|

|

|

The larger ring wouldn't fit in my vise so I used some all-thread along

with some washers and nuts to keep it in the right position while I cut

the excess off.

|

|

|

Again I used a piece of all-thread to pull the ring

together for welding. Once it was in the right position, I used a single C

clamp to keep things from moving while I did some tack welds.

|

|

|

Here is the six inch piece all welded. Now it's time to cleanup all

those welds.

|

|

|

A few minutes with a grinder and it looks much better now. I did this

for all the rings.

|

|

|

|

This is the base that will be attached to the floor. I'll be welding the

six inch ring to this piece and the four holes in the base will be used with some Tapcon fasteners, which will be

anchored to the concrete floor. Knowing what

size the Tapcon's were going to be, I also chamfered these holes accordingly.

The reason the largest ring will be used here (six

inches tall) is because

it might get kicked, or worse while people are playing the game. This

way it should protect the cardboard tube that much better so it doesn't

get beat up.

|

|

|

|

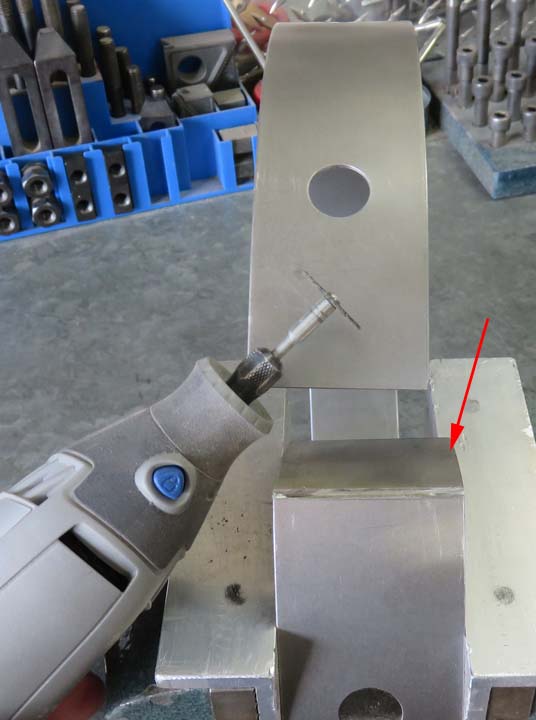

This base plate will be used with the two inch ring that

will be fastened to the ceiling. The four holes are

for wood screws to hold this in place and the center hole is for

electrical wiring. I'll revisit this project in a minute while I switch

to

another project.

|

|

|

|

I'm cutting out a piece of steel that was leftover from the rings

here,

which

will be used for as a trim plate on the cardboard

tube. This trim plate will be fastened with # 10 screws and there will

be a clear piece of plastic behind it. Think window here.

|

|

|

|

I decided to cut three pieces of material for the trim

plate at the same

time, mainly because I didn't know exactly how thick this trim plate

should be. Once I'm finished, I'll mess with each piece and see which one

I like best.

On the left we have a piece of mild steel that is .025"

thick, the middle is the same as the rings at 1/16"" and on the right is

.090" 6061-T6 aluminum (street sign material).

|

|

|

|

1

2

3

4

5

6

7

8

9 |