|

Working With Wood Continued

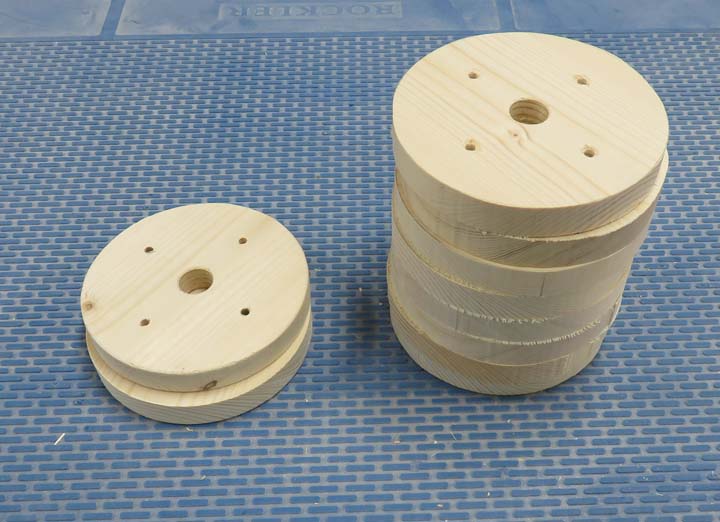

This small thin piece was easy to cut and it went quickly compared to

the larger/thicker ones.

|

|

|

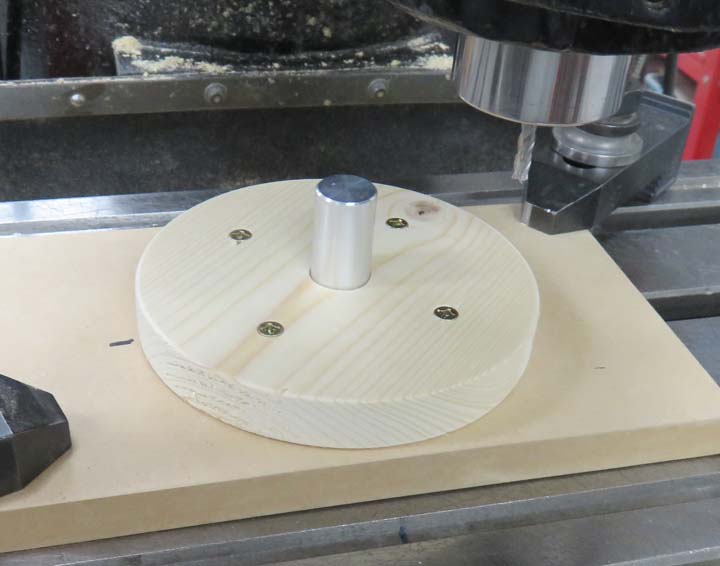

I switched back to my smaller tooling

which is perfect for these five inch rounds. Here you can see that I'm

using my aluminum pin along with two 10-32 cap screws and nuts to hold it with.

|

|

|

This didn't take long because I was able to use conventional lathe

tools. Now it's time to cut some steel.

|

|

|

|

Working With Steel

I'm going to use some 3/16" mild steel round bar to make some pins,

which will be inserted into the five inch round pieces. You'll get the

idea soon...

|

|

|

|

I used my metal cutting saw to cut the pins with but

quickly found out the blade that came with it wasn't ideal for this

smaller diameter material. My blade doesn't have the tooth count that is

really needed for this smaller material because it was bending it as I

cut though.

|

|

|

|

I ended up putting a thick piece of steel behind the bar

stock right next to the blade (not shown). This remedied the problem but I really

need to buy a blade that has a large amount of teeth to cut something

thin like this again. Note the blue bucket: I put a plastic guard with a mag-base covered with a rag to help catch the pieces as the flew off.

But it only caught about 50% of my pieces.

|

|

|

I deburred both ends on my belt sander and then put those into that dish

for later.

|

|

|

|

Working With Wood Continued

Here is another simple fixture that I used to put in the holes for

the pins. I'm using a 3/16" diameter end mill in place of a drill for

this operation.

|

|

|

|

My digital read out has some nice features, including

one for bolt circles. All you do is input some parameters, like the

radius of the bolt cycle, how many holes, starting point, etc. and then

hit go. The next screen that appears has the X and Y coordinates that

you need to dial to.

|

|

|

|

Once you have your numbers read zero, you're ready to

work on that hole (drill, ream, using and end mill, etc.). When you're

finished with that hole location, you hit "Next Hole" and it gives you a

new set of numbers that you move to. You keep doing this until you have

all your holes done, then replace your work piece and repeat the process

again. Very simple.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13 |