|

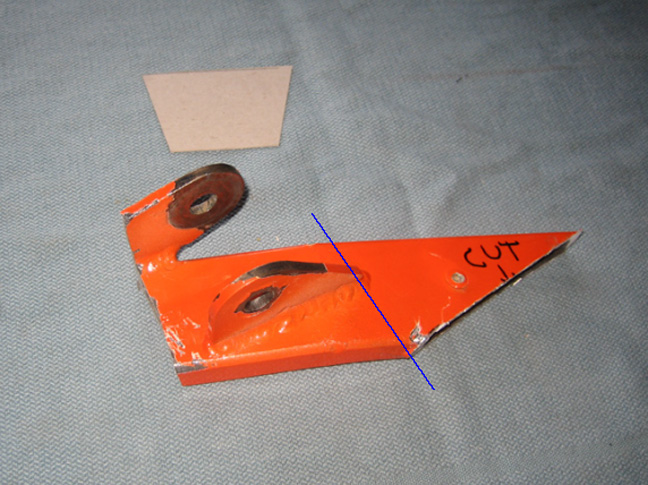

March 11th. Now that I have the cutting part

out of the way, I need to make the chassis structurally sound again. The

piece that needs to be made is the shape of the cardboard that you see

below (I seem to use a lot of cardboard but it works really well). This

small piece will go between the piece I just cut out (which is part of

the X member) and the main frame rail.

My plan is to make the new piece from my old one but it's going to be

close. At first glance it looks like it should be no problem but what

you can't see very well is the bend that it has. The bend runs close to

that blue line which may cause a problem with material that I may need.

|

|

|

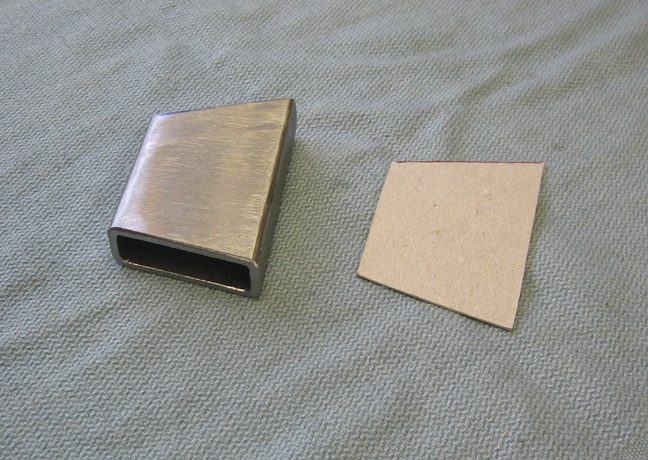

After a saw cut here and some milling there, this is

what's left from the piece above. It still has a slight bend in it but

that really won't matter for my application because this piece will only

serve one purpose, which is tying two pieces together. As you can see I

removed all the paint so it can be welded with no contaminates

introduced into the weld.

|

|

|

While I was making things I also made this end cap that will plug the

end of the X member that I just cut. It's made from 3/16" mild steel

with a small locating lip that fits right into the tubing. The thickness

of the plate that will show is 1/8" which is the same as the tubing

thickness. The chamfers on the four corners are to clear the radius on

the inside of the tubing.

|

|

|

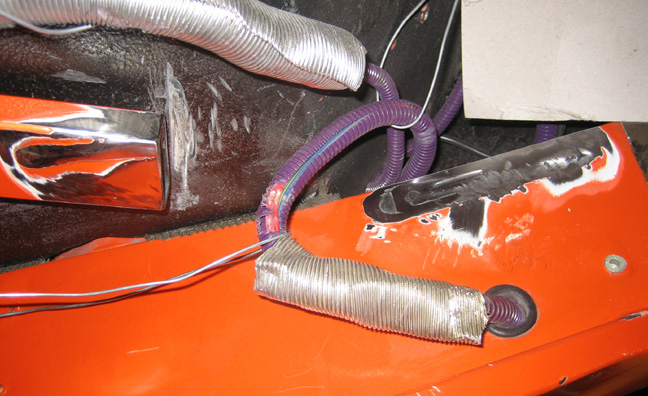

Here is a shot of the area that had the 1/2" saw cut problem which is

now flush with the frame rail. That rotary tool did a good job here and

then I finished it with a disc-sander. And you can see where I wasn't so

careful with my grinder and those wires. Instead of relocating the wires

which would've only taken a minute, I decided to hit one quick area with

my grinder. I hand held those wires out of the way so they wouldn't get

touched but once I let go of them for one second, this happened. It was

my fault for being lazy and what I should have done is untie them and

then use my grinder. I'm paying for that now because I'll have to fix

three of them pretty soon.

|

|

|

The piece that I made fits really well and by using a magnetic base to

help keep it from going anywhere, I'm ready to tack weld it in place.

The mag base is doing double-duty here as I'm using it as my ground wire

too. I took out the long rod that it came with and screwed in a fine

thread stud in it's place and then clamped the ground strap to the

threads.

|

|

|

My wooden creeper is just a little to tall while I'm welding so I pushed

it out of the way and used this piece of cardboard to lay on instead.

This is the same piece I used to cover myself while using the rotary

tool (notice the lines that folded around me). Even though I swept the

floor really well, there are still some little chips that I keep finding

there way into my shirt so the cardboard makes life much nicer. In case

you're wondering, that rag is soaked in water so I can dab here and

there when the weld is close to the floor. A bucket full of water is

just out of view to the left.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |