|

May 6th. The panels that cover the hole in

the floor need to be insulated so that's what I'm doing here. After

cutting out a piece of insulation that is a little bigger than the

panel, I'm ready to glue it on. The glue that I'm using is called Super

Trim Adhesive 8090 made by 3M. I used this glue when I did the

upholstery a few years ago and it's still going strong so I thought I'd

use it again here.

What you do is spray both surfaces that you want to bond and then

wait a minimum of five minutes before sticking them together. I've tried

doing this with less time but it doesn't work as well so follow the

instructions on the can.

|

|

|

Here is what it looks like after a quick trim with some

scissors. I drilled through all the holes from the other side and then

cut away a small area around each hole so the screw head would be

visible. The only reason I did the cutting is because once I screwed

them down, I couldn't see the tops anymore. This was done on the smaller

panel as well.

|

|

|

|

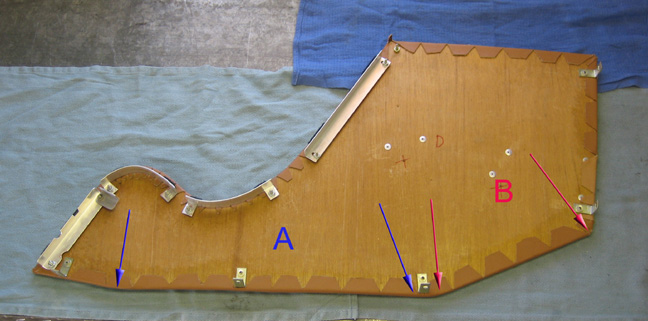

The insulation was the easy part but now I need to modify my console

because it doesn't fit anymore. What you see here is the drivers side of

my center console and after adding the insulated panels from above, the

floor sits higher in the area that the console sits on now. And with the

top of the console fitting tight against the underside of the dash

(before I added the new panels) the side pieces won't fit anymore.

If you remember the new aluminum panels that cover the hole in the

floor are raised slightly to clear the transmission but I had no other

choice in the design if I wanted them to work. The panels sit about 3/4"

higher now which will be the same amount that needs to removed from the

bottom of the console (section A). This same panel is also hitting

against another area (section B) which will require about 3/8" to be

removed as well. This was not anticipated at all but I'll have to deal

with it.

The straight and bent pieces near the edge are made out of 3/4"

aluminum angle which supported the center section of the console. I'll

need to remove most of them for what I have planned.

|

|

|

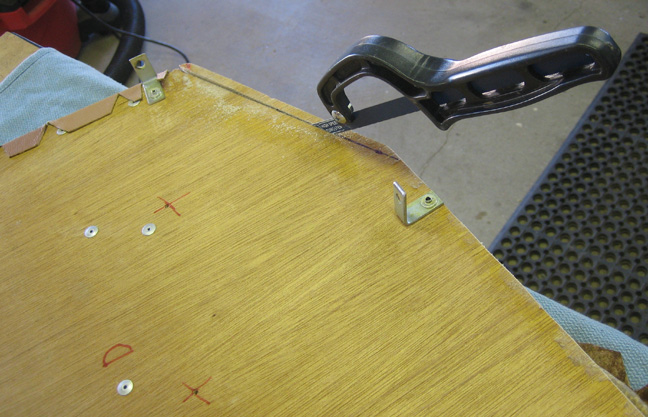

Here you can see I've removed the leather from the wood and pulled the

material away from the padding a few inches too. I'll need to make sure

the material is completely out of the way when I do any cutting because

the last thing I want to do is to buy more leather. The reason I don't

what to buy more material is because the color runs in lots and after

this many years I'm sure I won't get the same exact color.

|

|

|

Once I laid out some lines, I used a hand saw which made quick work on

this thin piece of wood and foam. The bracket that you see near the saw

has been turned 180 degrees while I was making the cut near it. I'll

have to remove and relocate two of them (on each side) because they're

to close to the edge after cutting.

|

|

|

Speaking of cutting, I'll be doing more of that here. The blue tape is

about the shape I'll end up with once I'm through because the raised

area that I had with my old shifter won't work with my new one. This

area needs to be removed because the new shifter is in a different

location and it doesn't pivot like the old one did. The old one had a

pivot point a few inches below the peak but the new one pivots close to

the floor and it's in a different spot. What I'll be doing is similar to

before as I'll need to pull back the leather to make room for another

cut.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |