|

Here is the back of the console and you can see how I fastened the

center piece. I used a bunch of 8-32 screws to hold some 3/4" aluminum

angle in place which has been cut and bent as necessary. This angle is

to help fasten the center piece which is held in with hook-and-loop.

What I did was put half of the hook-and-loop on the angle and then the

other half on the center section. I'm not sure how other people do this

sort of thing but it worked good for me.

|

|

|

|

Here you can see the material has been pulled away and

that I've made my cut. I also put a small radius on the wood where is

starts down the angle if you look close.

|

|

|

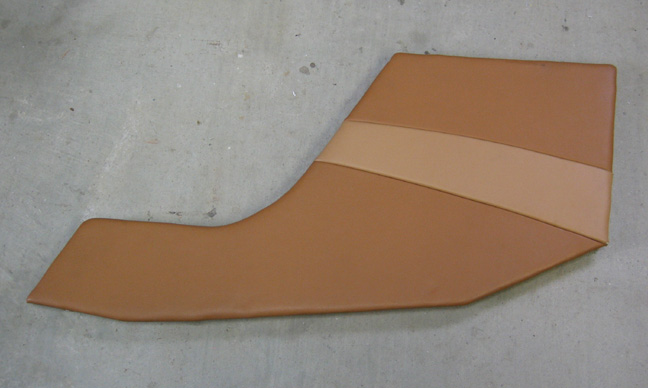

In this shot I've trimmed the material and I'm ready to do some gluing.

The hardest part about doing this kind of thing is the corners. What I

do is the longer straight sections first and then slowly cut and shape

the corner areas. I'll go into more detail later.

|

|

|

Once I had all the material glued I started placing my support pieces

back on. I made these support pieces adjustable by slotting the holes

slightly which worked out really well. I only used three of the four

supports because after cutting off the one section the support piece was

rounded which I don't need anymore.

|

|

|

|

Here is the new look with all the changes and with it

all put back together. Now it's time to get it back in the car to see

how it looks but before I can do that I'll need to take care of some

other details.

|

|

|

|

What I'm doing here is making a little more clearance for my feet. On

the right you can just see the passenger side console which is ready to

be fastened down. When I screwed down the drivers side (console) I found

out that my feet really could use more room. What I'm going to do is

move the drivers side console towards the center about 1/2" to 3/4".

What you see below is a quick clamp that I made out of aluminum

utilizing one of my old screw holes that held in my console. Under the

clamp is a 6-32 screw threaded into an aluminum block that has been

glued to the firewall. I did this for both places that screw into the

firewall (which is right below this one just out of view). I left the

clamps in place over night to make sure that the glue dried before using

them. I didn't want to use a riv-nut here because the firewall thickness

is about the same as the riv-nut length which means I might drill

through it so I didn't chance it.

|

|

|

|

24 hours later.

Here you can see one of the aluminum clamps with the screw still

threaded in. The clamps were pressing against the tops of the screws

holding them in place while the glue dried. To the left of the new clamp

is where my old screw hole was, which was made from some leftover

fiberglass while I was building the car years ago. I would have used

fiberglass again but I couldn't find any pieces so this is why I used

aluminum. They seemed to bond just fine and now it's time to see how

they work.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |