|

This is what the parts look like all finished and you can see what the

second tool did (1/8 radius) at the top better now (left). On the backside you can

also see what the

corner rounding end mill did at the top (right). I drilled and tapped 1/2-20

threads in three places so I could adjust them side-to-side if need be.

The holes are placed 5/8" apart and are 5/8" deep. Total time

on the second side was about 2 minutes. I know they are kind

of simple looking but I wanted something quick so I could get the car on

the road. On the other hand I don't think anyone else will have the

exact same pads in their car so I guess you could say they're one of a

kind. I might make something different in the future but I'm not sure

what yet. Oh by the way...I ended up with three parts.

I made a

short video to show some of the

cutting action of the first operation if you'd like to check

it out (20 mb). This should give you a better idea of what it looks like to machine

something like this.

|

|

|

Here are the finished pads bolted in place. They feel

pretty good when I push on them but I have something else to deal with

now and that's my throttle pedal being to close to the brake. Even

though I moved the gas pedal over to the right by about 1 1/4" awhile

back I still don't have enough room here. In order to get enough spacing

between the clutch and brake pedal pads, I'm find myself pushing the gas

pedal while hunting for the brake. My foot just catches the corner of

the gas pedal every now and then so I need to move the gas pedal

assembly over a small amount to be safe here. I have an idea for this

because it's something I've been thinking about ever since I moved the

center console. Stay tuned.

|

|

|

|

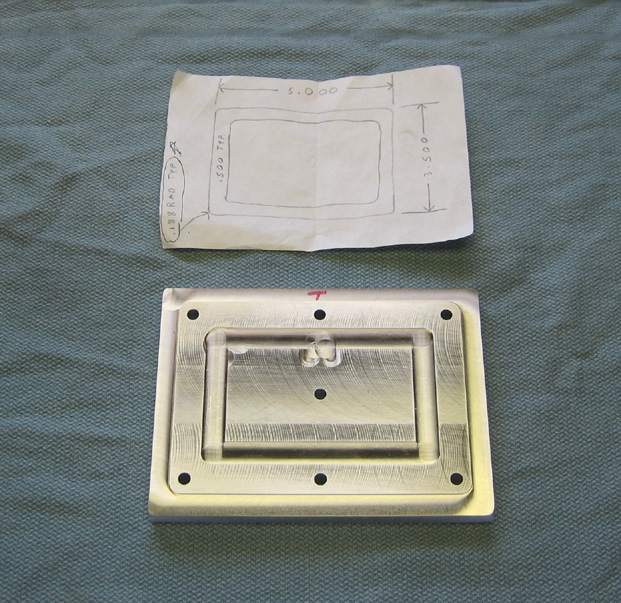

I talked about making tooling in order to make certain types of parts

and this is what I'm doing here. What you see below is a sketch of the

trim ring that will go around my shifter. The trim ring will be made

similar to the switch panels that I made on the center console which are

1/4" thick. When you're working with something thin like this you can

normally get away with just a vise setup. But when you have a radius on

all the edges that are 3/16" in size, that radius ends up going almost

all the way to the bottom of the part thickness. With that being said, there is no

way I could machine a radius like this without the bottom of the cutter

hitting the vise jaws so this is where tooling comes in.

What I needed to do is to make some tooling to hold the part while I

machine it along with enough clearance built in so the radius cutter

would work properly. The aluminum tooling fixture will provide these

features and I can hold this fixture in a vise. The six holes around the

perimeter are used to hold the trim ring to the fixture. The hole in the

center is my starting point which is where I will need to indicate and

then tell the machine where my work coordinates are.

|

|

|

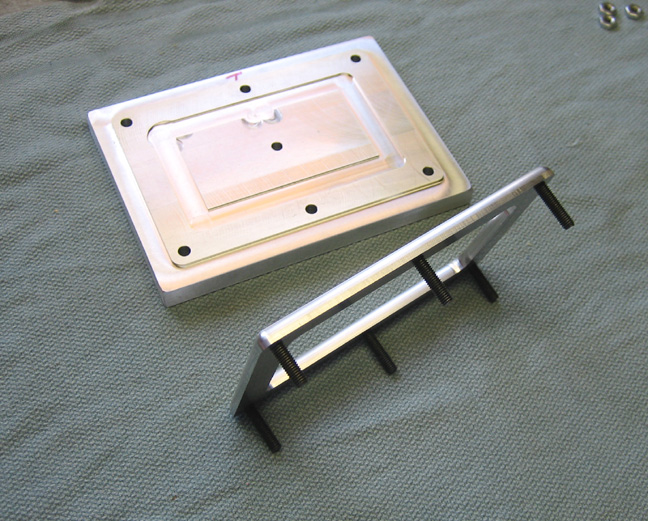

I used 10-32 screws that I cut the heads off of to hold the trim ring to

the fixture. The reason I cut the heads off is because the trim ring

will have blind holes tapped into it like the switch plates do so you

don't see any fasteners holding it in place. This makes it nice to look

at with no screws showing when it's installed but it's much harder to

make this way.

|

|

|

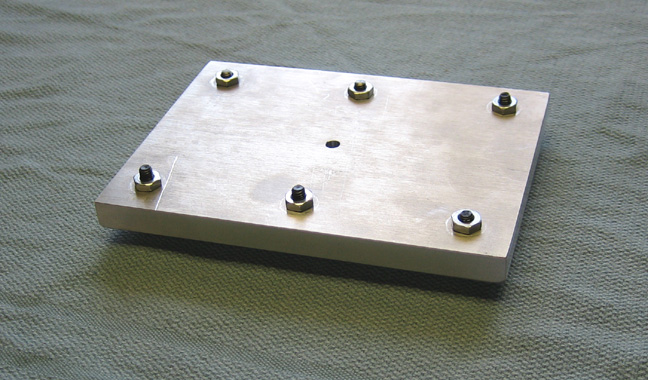

Here is the bottom side with nuts holding the part in place. The only

bad thing about this tooling is that I have to remove the fixture to put

another part in. I made two parts just in case I mess up one.

|

|

|

|

Here is the finished trim ring after a little hand work with my buffing

wheel. The radius matches the switch plates and it should look like it

belongs their once it's screwed in place. The inside of the trim ring is

the same size as the opening in the console and all the sides are 1/2" wide.

Now I need to make a boot which I still don't have a clue how to do but

I'll give it a shot soon. I'm pretty sure I'll need to do some sewing on

it so that will be a first for me while working with leather.

I had to bleed the brakes and clutch again and I adjusted them both

too. I also removed the ramps that the rear tires were sitting on and

put jack stands in their place. The reason for this is so I could start

the car to try out the clutch and then have the tires spin in the air.

Come to find out the clutch didn't want to disengage properly so I

adjusted the pushrod to make it longer and that seemed to make the

difference. By making the pushrod longer it pushed the plunger deeper

into the master cylinder putting a preload on it if you will. I'll be

test driving the car next week to see how things work and find out what might

need to be adjusted or tweaked on. I can't wait!!

Next week I'll need to start making a boot, relocate my throttle

pedal and if you were wondering, I ended up with only one part (below).

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |