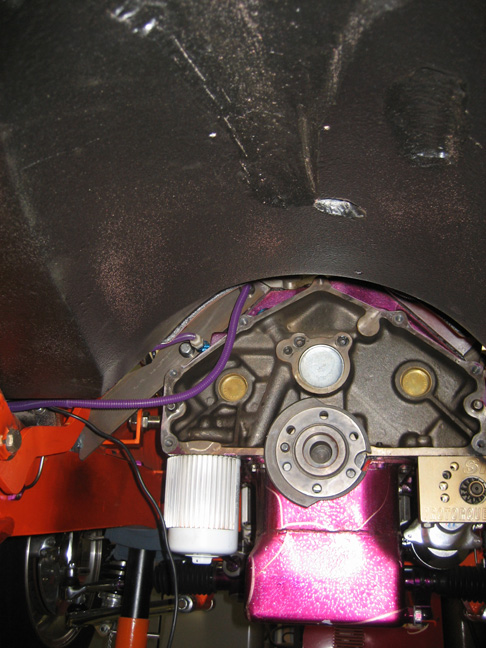

I haven't seen this shot before because I've

always had a transmission attached to the motor. It sure does look

different with it empty now. The V shaped area at the top was clearance

for the old trans that I ground away because of how large it was.

Somewhere in that same area is where a new rectangular hole will be

added for a shifter to poke through. Once I get the trans mounted in

place, I'll mark the floor and then do some cutting.

|

|

|

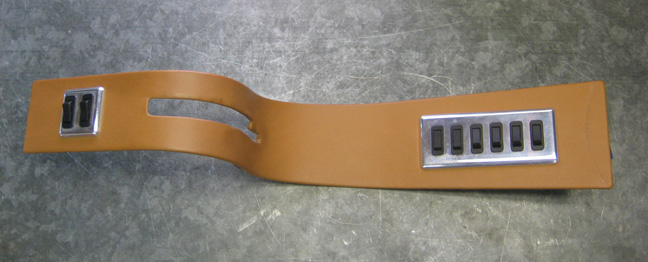

Moving to the interior now (remember I'm trying to keep

busy while waiting for parts) here is my center console that looks like will have to be

altered too. See that slot where my old shifter was? That slot area is too

long and to narrow for a manual gear pattern which will have to be

addressed. I'm thinking that the raised swoopy area where the slot is

will have to be a little flatter which means making this piece over and

reupholstering it again. Once I get the new trans installed and see

where the shifter gets located, then I'll be able to see what needs to

be done. This didn't come as a surprise to me because while I was

thinking about the trans swap this area crossed my mind. I may have to

modify the sides of the console as well but I'll have to wait and see

once the new trans is installed.

|

|

|

I also noticed how bad the switch panel looked once I had it out so I

can take this opportunity to take it apart and make it look a little

better. Speaking of opportunities, I've been wanting to do something

else to

this panel for awhile now but I didn't want to deal with taking it all

apart to do it...till now that is. Stay tuned for what I have in mind.

|

|

|

I found something else to keep busy while I'm waiting for parts to

arrive. I noticed my exhaust adapter that bolts to my heads didn't

look flat. See all the dark area on the surface? That should be a little

more even colored which means some of the exhaust gases are blowing by

the gaskets. I started using a flat file on them to clean them up and

found out pretty fast they weren't very flat. If you look at the top one

you can see where the file hit on both ends but after a few minutes of

this I could tell this wasn't the way to go.

|

|

|

What I did was take them to work and milled them till they just cleaned

up which took about .020 to do the job. That would have taken me a long

time with a file but milling them only took a few minutes. That surface

is much better now wouldn't you say? And the gaskets should seal much

better now too.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |