|

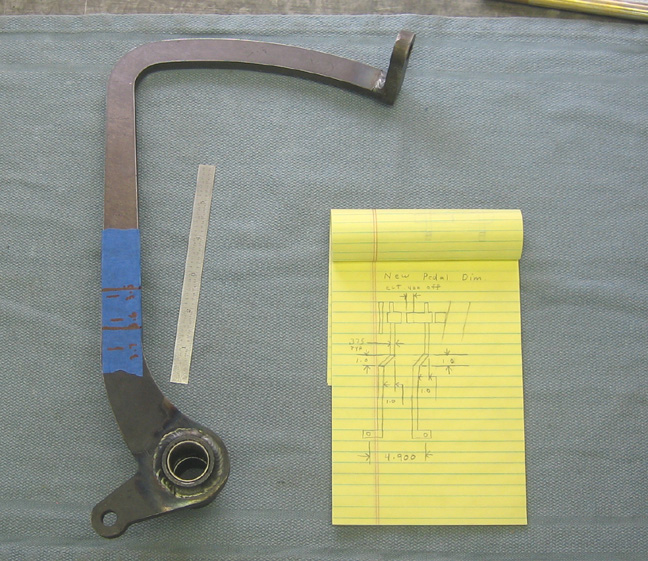

March 17th. My brake pedal fits pretty good

now after the cut-and-weld session that it received so now it's time to

do more of the same with my clutch pedal. The only difference is

the one inch piece that gets cut out will be in a different spot. If you

look at the blue tape you can see some numbers on it along with two

lines running all the way across. Those two lines are 1.000" apart which

is where the cut will be. The reason this cut will be so much lower on

the arm is because I need to clear the frame right after the pivot

point. I'm also going to remove .400" from the pivot point end or

boss, for a

total of 1.400" of off-set to the right.

|

|

|

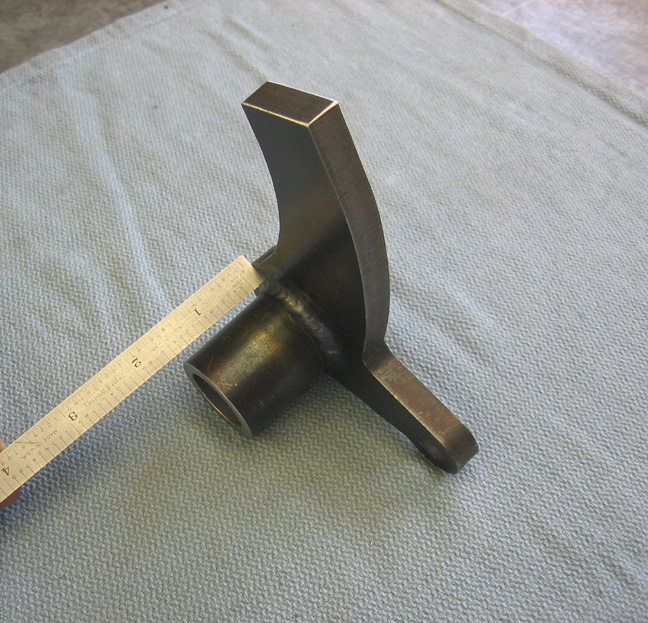

Here you can see the 1.000" section has been removed

along with a freshly cut surface on the pivot boss. With this cut being

lower in the arm compared to the brake pedal, the piece that I made had

to be a little wider to compensate.

|

|

|

In this shot you can see the section that I removed the .400" from which

will allow the clutch pedal to be closer to the brake now. This should

put both pedals right where I need them according to my cardboard

mock-up that you saw earlier with the scale attached to them (if I did

my math correctly).

|

|

|

|

Here is the clutch pedal welded back together again and it got the same

type of welding as the other one.

|

|

|

|

This is the clutch pedal arm and that area right next to it needs to be

removed so it can have free movement. Time to break out the saw and

rotary tool again.

|

|

|

This is what things looked like once I was through cutting. That air

tool really make a mess of things but it works very well. I used my air

hose and blew off everything right after I took this picture because I

couldn't stand looking at it. Notice that I have all the sparkplugs back

in along with tape covering the exhaust ports too.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |