|

Here you can see what the u-tabs look like on the collectors. Once

you have the header tubes or the tubing reducer inserted, a bolt and

locknut hold the two together. This system works very well but it

doesn't seal 100% as you can see by the exhaust on all the surfaces. On

the other hand, it sure does make it easy to work on. If you look close

you can see a letter D and P on each u-tab. This is so I can tell them

apart once I get them back from ceramic coating.

|

|

|

Here you can see the new exhaust system running by the

new bracket and snaking through the chassis. The purple colored plastic

covering has wires in it and will be located against the chassis later.

This pretty much completes the exhaust system except for recoating them

with ceramic coating which I'll be sending out in a day or two. While they're

getting recoated that will give me a chance to work on some other stuff

because coating should take a week or two.

|

|

|

Once I was ready to go in for the day, this is what I had to walk

across. It had been raining most of the day and at times very hard. My

garage is detached from the house which is about 100 feet away so the

floor of the house got a little muddy when I came in. The wind was blowing pretty good

and the temp was in the low 40's while I was working that day with snow

in the forecast for that evening. Sure enough we got a dusting of snow

overnight which was great because we don't get much here in So. Ca. like

we use to. If this keeps up I'll have to put a heater in the garage.

|

|

|

|

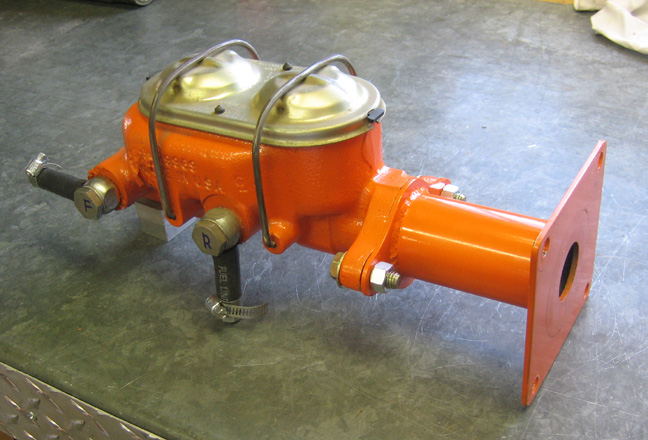

Next I'll be mounting the clutch master cylinder to the chassis. This

one is made by Wilwood and came with the pedals and brackets that I

received from Total Coast Involved awhile back. This is a nice kit and

can be used a few different ways. At the top we have an aluminum master

cylinder with a 3/4" bore. You can mount it to the side of the chassis

through those two holes that you see or from the front with two more

holes that go through the face of it. At the rear is where you run your

line out of and it has a bleeder valve back there too.

Below the master are three different ways of using a reservoir. There

is a large and a small one depending on what kind of clearance issues

you have or you can remote mount your reservoir if you'd like. It comes

with a bracket, hose and some fittings depending on your application.

|

|

|

|

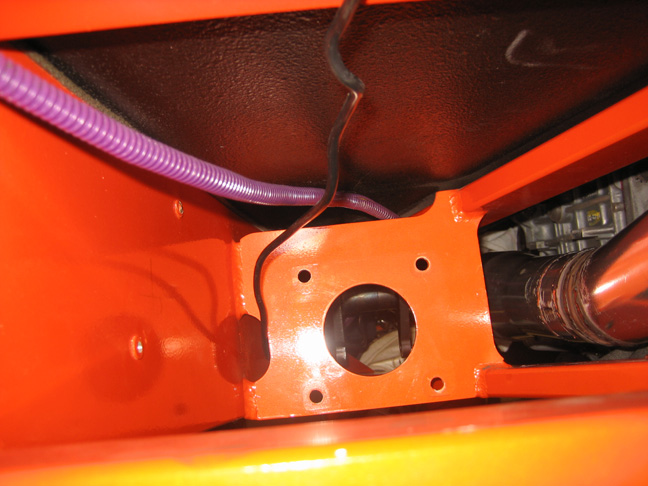

My original plan was to use the two threaded bungs that came with the

kit and weld them to the main frame rail on the left. But after doing

some measuring and thinking, I don't think I'll be doing that after all.

I made a few sketch's of different ways of doing things and I had a hard

time deciding exactly what to do. Once I was happy with one idea,

another one would come to mind and then I'd start down that path. This

happened over and over again so I guess I'm going to wing it here. On

the other hand, there's more than one way to skin a cat. My old brake

master cylinder was mounted to an adapter that I made which bolted to

those four holes in that 1/4" steel plate that you see below. The

pushrod ran through that large hole and worked pretty good for many

years. The reason for that large hole is because my chassis came with a

brake booster for power brakes. I wasn't able to use the power brake

booster back then because someone bought to big of a camshaft which

didn't make enough manifold vacuum to run the booster :-] This is

why I made the adapter in the first place and have been running manual

brakes since day one.

What I finally settled on is making an adapter plate that will bolt

to the bracket below and then mounting both masters to it. One reason

for making this new one is because the clutch pushrod that came with the

kit is shaped like an S and I can't see how to make that work for my

setup. I'll have to make new pushrods once I'm done here but that's no

big deal. Take a good look at this area because it won't look like this

very long.

|

|

|

Here is my brake master cylinder bolted to the adapter that I was

talking about. The adapter length is the same as the power brake booster

was, in case you were wondering. I decided to keep the adapter but I'll

do a few modifications to it. The adapter is made out of 1/8" thick

steel and is very ridged. I'm not sure how I'm going to fasten it yet

but I'm sure I'll dream up something along the way.

|

|

|

|

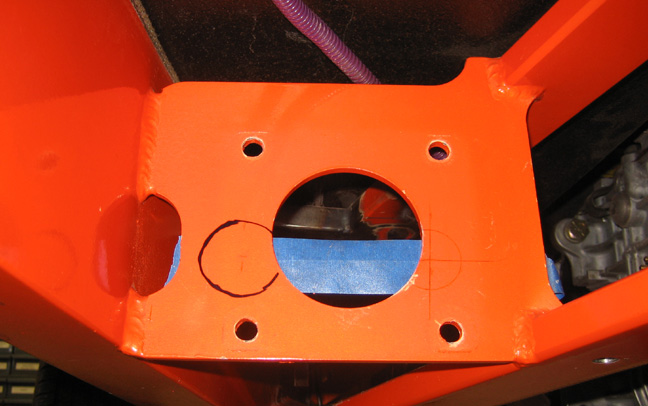

I'm doing some layout here and getting ideas of where I'm going to be

drilling some holes. If you look close you can see a crease in the tape

which is where I drew a line on the other side of it. That line

represents where the two pushrods will end up. What I did was place a

square against the other side of this plate till I had it lined up with

center of the holes in the pedals. Once it was right where I wanted it,

I marked the tape and drew my line across it. Now this is a critical

step because if you get your pushrod out of alignment they won't work

very well. Plus you can get premature wear on your master cylinder which

is a bad thing.

I transferred my line from the other side and started laying out this

side. The dark circle is where the clutch master cylinder will be

mounted and to the right are some layout lines where the brake pushrod

center line will be. I'm kinda stuck with where all these holes will be

drilled because of where the pedals ended up at. I plan on staggering

the two master cylinders with the brake being towards the rear. I

thought this would work best because if they were mounted side-by-side,

it would be very hard to get at and fill the clutch master with fluid

when the brake master was in the way.

The distance between the two masters are at a minimum here which is

3.200" apart. And I had to figure out where to place them from side to

side so both pushrods would run down the side of the mounting points of

the pedals and not in the middle of them. If the pushrod didn't run down

the side of the pedal mounting point, they would end up being at an

angle which again is a bad thing. I gave myself a little extra room here

which means if my calculations are correct, I'll need to make some

spacers to go between the pushrods and pedals later. I'd rather make a

spacer than have an alignment problem.

|

|

|

|

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

|

|

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53 |

|

54

55

56

57

58

59

60

61

62

63 |